Organ-on-Chip

Next Generation Cellular and Organotypic Assays

Senior Principal Scientist

Lab-on-chip (LoC) systems have been developed and applied in academic research for more than a decade and are now increasingly used in various industrial applications.

However, technology transfer from academia to industry is often hindered by the limited fabrication methods and materials used in academic research and startups. Currently, prototype microfluidic systems are mostly made of polydimethylsiloxane (PDMS), a polymer that has the property of adsorbing small molecules and is limited for mass production. The goal of this project is to develop a new generation of versatile materials, coatings and fabrication processes for LoC systems, focusing on the requirements of organ-on-chip technology that combines biocompatibility and scalability.

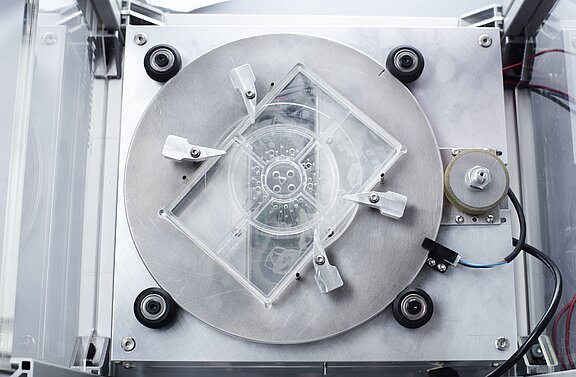

The 3R Center is well equipped with chip fabrication laboratories with a wide variety of patterning and joining methods such as lithography, laser cutting, hot stamping, 3D printing, thermo-mechanical joining and laser welding. Various techniques and methods, such as providing samples extracted from chips, RNA expression, organ-on-chip immunohistochemistry and gene expression analysis, and many more, are offered as services.

Test system development

- Design and development of microfluidic solutions for cell applications.

- Combination of microfluidics, biomaterials and 3D tissues

- Development of microphysiological organ-on-a-chip systems

- Functional testing and validation of in vitro models

- Development of fluidic solutions for cultivation and differentiation of stem cells

Evaluation of external microfluidic platforms

- Establishment of microphysiological tissue models and assays in external microfluidic platforms

- Validation of phyiological cultivation parameters

- Determination of viability and functionality of tissue units

- Establishment of endpoints and assay developments

- Substance testing